Govan Wet Basin

Supporting UN Sustainable Development Goals

Project description

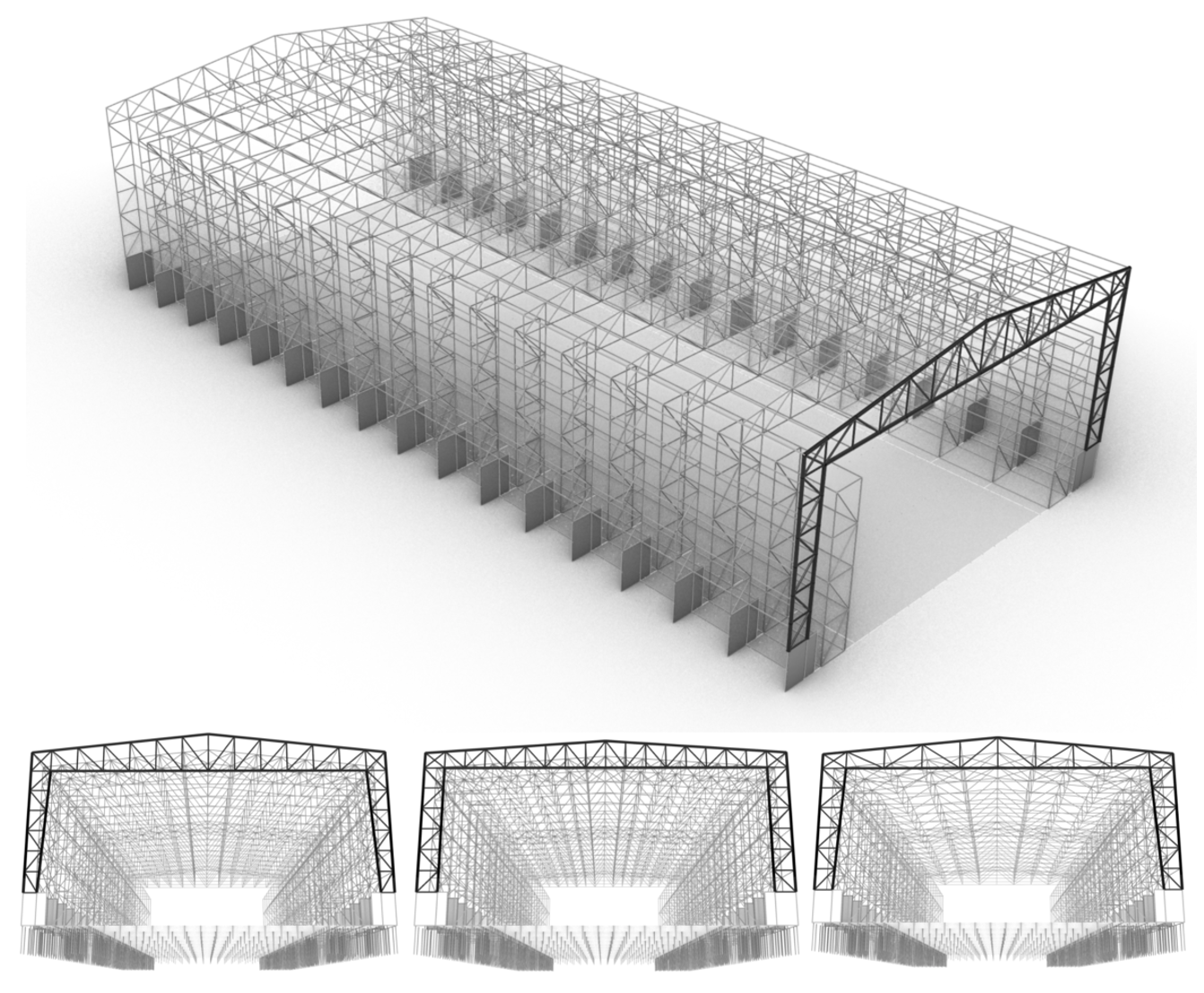

The Govan Wet Basin redevelopment in Glasgow reclaimed a former dock to create a stable platform for the Janet Harvey Hall—a covered assembly hall measuring 170m by 80m. Equipped with two 100-tonne and two 20-tonne cranes, the facility enables parallel construction of two Type 26 frigates under cover. Over 6,000 tonnes of steel and 20,000m³ of concrete were used to deliver a hall that improves efficiency, protects production from weather and ensures long-term resilience for Clyde shipbuilding.

Design constraints

The riverside site was bounded by the operational River Clyde and existing shipyard infrastructure. Reclaiming the wet basin posed challenges in stability, settlement and integration with the quay wall. The hall required clear spans, high clearance, and crane capacity for large hull sections, all while balancing cost and constructability. A fast-track programme demanded rapid delivery with minimal disruption to shipyard operations, adding pressure to coordinate marine works and steel superstructure.

Engineering response

Controlled infill raised the wet basin to quay level, supported by driven piles for stiffness under heavy loads. A long-span steel superstructure was designed with optimized trusses and robust connections to carry cranes while maintaining open space. Parametric modeling enabled real-time optioneering of grid spacing, truss depth, and crane positions, allowing design to evolve alongside the brief. This digital approach accelerated procurement and construction planning, ensuring efficiency and cost control.

Impact

Parametric design tools were key to meeting programme and cost targets, enabling overlap of design, procurement, and planning. The integrated approach delivered a robust, flexible hall that maximizes internal efficiency and protects production from the elements. Structural optimization reduced material use, lowering costs and improving sustainability. Completed in under 20 months, the project demonstrates how digital tools and engineering expertise can transform complex marine sites into high-performance industrial facilities.

Mark Boyle and Theo Mourtis worked extensively on this project while they were with Robert Bird Group.